Material:ASTM A536 Grade 65-45-12

Standard coating:Epoxy Power

Optional coating:Painted;Dacromat;galvanized

Color can be as per your requirment

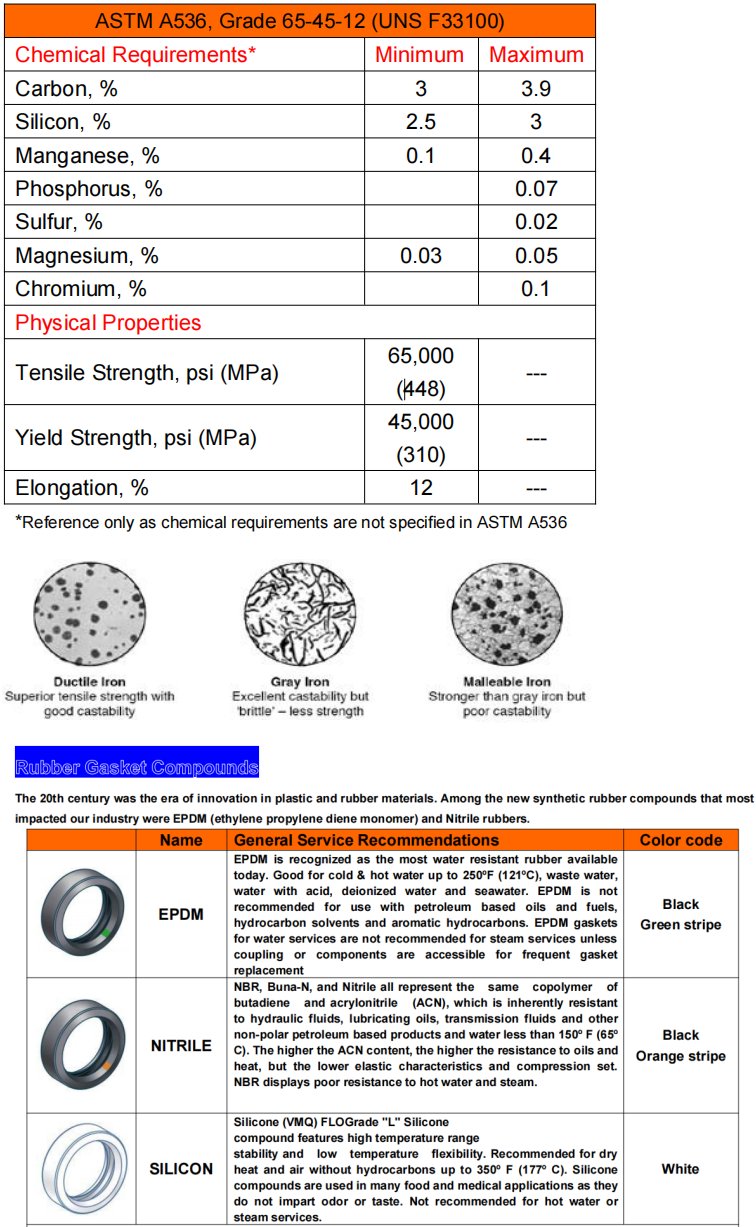

Ductile iron is an ideal material for grooved mechanical components, as it provides similar or greater strength to that of wrought or cast steel piping materials such as;forged steel flanges - ASTM A105, carbon steel valves-ASTM A216 WCB, wrought carbon steel pipe - ASTM A53 Gr. B, etc. Most FLO components are made of ductile iron conforming to ASTM A536 Gr. 65-45-12 Ductile iron was first invented in the U.S.A. and U.K. in the late 1940's. Superior strength was achieved by crystallizing graphite in the shape of nodules. The result was ductile iron that had tensile and yield strength properties that were equal to or greater than some steel castings. This superior strength combined with ductile irons excellent cast ability helped to reduce the weight and cost of many components. Because of these advantages and benefits, many components have been converted from gray iron, malleable iron and steel castings to ductile iron over the past 60 years.